Part I: Introduction to a successful MES program

It is no secret that companies need to constantly keep improving their products, services and ways of working in order to stay in the game. Production involves several processes that need to be continuously developed if you wish to remain competitive. Improving production means making processes more efficient and agile and reducing the amount of waste. Digitalization is one approach that provides tools for this; it is one way to collect data and process it into information and, further, nurture it into wisdom. In companies with several production facilities, digitalization means implementing a complete corporate-wide Manufacturing Execution System – a Multi-Site MES.

When first beginning to implement a MES system, there is a great temptation to start small and extend the system on the go. However, if you neglect the fact that the ultimate purpose, in the end, is to run the MES in several lines, departments and production sites, the full potential of MES will also be neglected.

A Multi-Site MES program can be quite an elephant. They say that the way to eat an elephant is one bite at a time. Sounds easy and simple. But where should you start? Which parts should you focus on first? How big bites should you take? Who are the people who should join forces to work on the big project and what kind of teams should you have? Which tools should you be using? How should you prepare for the project? Do you need any special spices?

This blog series is about sharing best practices, standard-based knowledge and useful information on how to implement Multi-Site MES as we at Roima see it.

We will focus on this key question: How to succeed in a Multi-Site MES program?

About this blog series: What to expect

In this blog series, we are going to tackle the question of how to succeed in a Multi-Site MES program. We will provide you with some useful tools, techniques and a mindset that you need to succeed, and cover different angles that you should consider before embarking on a Multi-Site MES program.

Naturally, all Multi-Site MES programs are unique, but the underlying problem and the way of handling complexity throughout the project remain the same. We will discuss the best practices, references and standards that are there for you to rely on and give you some good tools for identifying, managing and reducing complexity in different phases of your Multi-Site MES program.

As you will learn in this blog series, it is not only about different phases of your program but also about the different levels of your organization that need to deal with complex problems within your Multi-Site MES program.

In this first part, Introduction, let’s start by looking at some basic concepts and some standards and frameworks that provide the foundation for this blog series.

What and why MES?

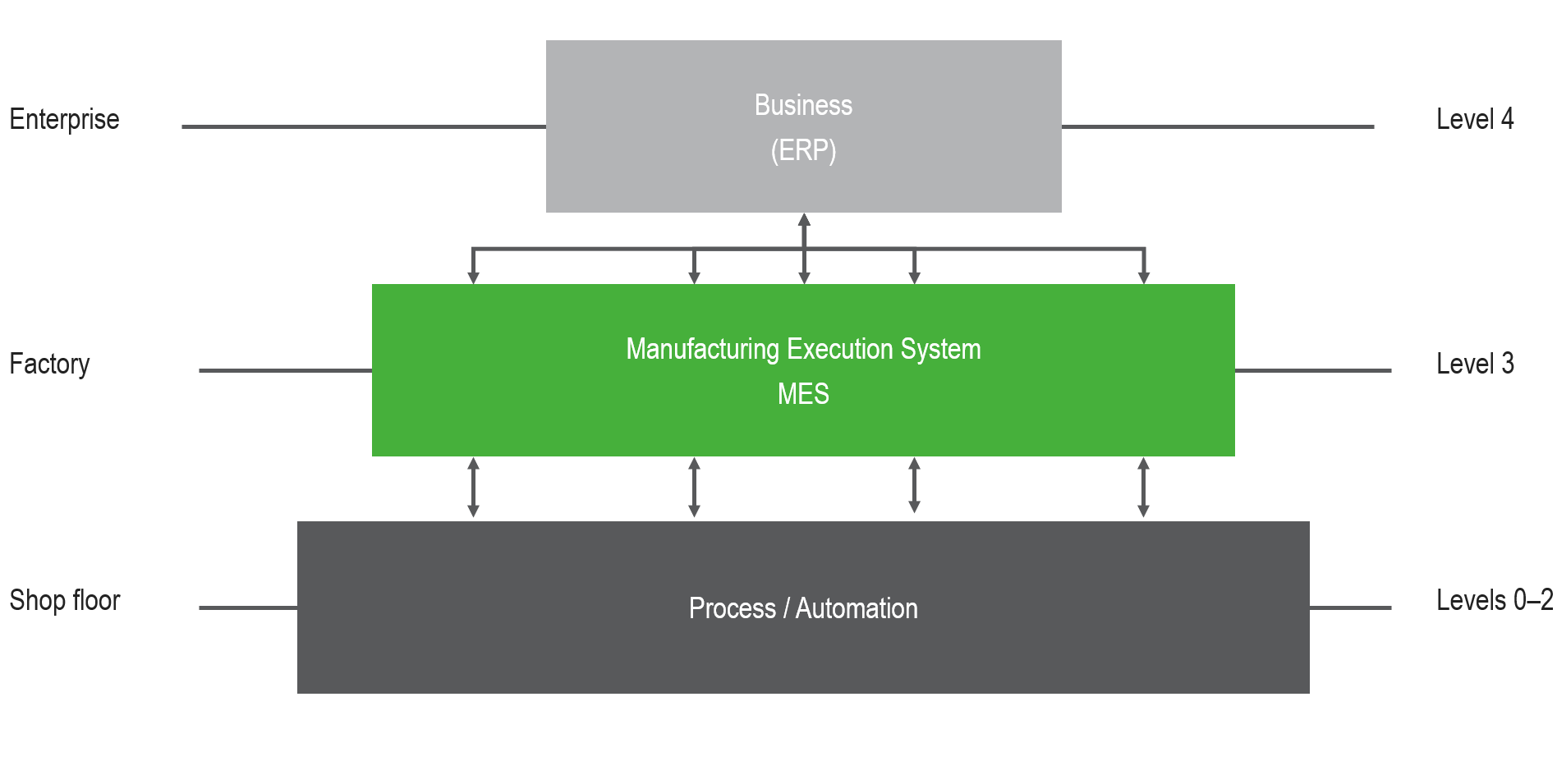

The acronym MES stands for Manufacturing Execution System. It is typically a system layer above shop floor systems and below an enterprise resource planning (ERP) system. MES usually performs manufacturing activities described in the ISA-95 standard, related to production, quality, inventory and maintenance.

Multi-Site MES, in turn, is a manufacturing execution system that is used simultaneously at several sites within the company. It introduces a common way of reporting, common KPIs and common practices to drive transparency to manufacturing across all sites.

In addition, Multi-Site MES motivates sites to establish common processes and common ways of working, thus allowing good practices to spread faster from one site to another and from one process to another

When implemented right, MES and especially Multi-Site MES will bring several benefits. On the top line, better quality and traceability increase sales, and optimized throughput increases production volume. Further, MES allows for faster new product introduction. On the bottom line, material yield, asset performance and workforce utilization increase.

In addition, MES serves as a tool for continuous improvement and facilitates the spread of best practices across units.

Standards and commonly used frameworks as the foundation

In this blog series, we will rely on many commonly used and widely accepted best practices, frameworks and standards, including the ISA and ISA-95 standards, MESA model, and smart manufacturing, as well as on activities such as business process modeling, and approaches such as Model-Driven MES. Let’s briefly go through each:

ISA

The International Society of Automation (ISA) provides training, certifications and standards in its field. As it is stated in ISA.org: “Automation standards from ISA – a global leader in industry-developed, consensus standards for more than six decades – serve as best-practice guidelines that direct proper system design, implementation, operation, and maintenance, and promote plant and operational reliability, safety, and security.”

ISA-95 is a standard that defines common terminology, information models and various processes in different industries, including manufacturing. ISA-95 serves as the foundation when defining the role of MES and how it will interface to other systems. We will be referring to ISA-95 in several future blog posts.

MESA

Manufacturing Enterprise Solutions Association (MESA) is a non-profit organization for manufacturing companies, system integrations, system providers, consulting companies, trainers, lecturers, students and others who are interested in improving results in manufacturing. MESA utilizes the ISA-95 standard and provides tools to implement it.

As MESA describes itself: “As an educational association, MESA provides models that help those from a variety of levels and disciplines within the manufacturing and production enterprise to converge on common views of what they need to accomplish and how enterprise solutions can assist. The objective is to provide a platform for mutual understanding and planning for increased performance.

To this end, MESA has developed several models over the years. The current model, developed in 2008, spans from enterprise-level strategic initiatives to business operations to plant operations and actual production. It shows the interrelationships between strategies, enterprise-level operations, and plant operations. Objectives cascade down, and results are reported up against those objectives. It also provides a conceptual illustration of how events in the plant operation feed and inform all other events, and how aggregate views from the enterprise can drill down through operations to the real-time production views.”

Picture source: http://www.mesa.org/en/modelstrategicinitiatives/MESAModel.asp

Smart Manufacturing

As defined by MESA Smart Manufacturing Working Group, Smart Manufacturing is “the intelligent, real-time orchestration and optimization of business, physical and digital processes within factories and across the entire value chain. Resources and processes are automated, integrated, monitored and continuously evaluated based on all available information as close to real-time as possible.”

In this blog series, we will be tapping into the concepts and ideas also described by MESA Smart Manufacturing Working Group.

Business process modeling

The acronym BPM stands for business process modeling. Business process modeling is the graphical representation of a company’s business processes or workflows, as a means of analyzing, improving and changing them. Often, the goal of business process modeling is to increase process speed, improve quality, or reduce costs in some way.

In the context of MES implementation, business process modeling will be used to build a business logic that will be implemented in MES.

Model-Driven MES

In Model-Driven MES, the business process models are used for building the functionalities of the MES system. The Model-Driven approach is meant to increase productivity by maximizing compatibility between systems (via reuse of standardized models), simplifying the process of design (via models of recurring design patterns in the application domain), and promoting communication between individuals and teams working on the system (via standardization of the terminology and the best practices used in the application domain).

Model-Driven MES approach bridges the gap between the customer and vendor, narrows down the gap between specification and implementation. Model-Driven MES taps into several benefits that we will be covering in future blog posts.

Naturally, there are some other acronyms that also have a role to play in this big picture, such as MOM, MIS, ERP, APS, WMS, to name but a few. We will discuss these acronyms in more detail in the future blog posts, as well as the roles of different systems and the topic of selecting technologies.

Conclusion

Digitizing production is one way for a company to stay competitive. In that context, MES is needed to bring together the data from the different shop floor systems. However, implementing a Multi-Site MES that creates value for the company is a challenging task.

In this blog series, we will cover different points of view that you should take into account on your journey to implementing a successful Multi-Site MES. We will be relying on standards and commonly used best practices and frameworks, such as the ISA-95 standard and the MESA model, and also share our experiences of applying these methods in Multi-Site MES implementations.

-

Part II: Complexity of Running a Technology

Part II: Complexity of Running a Technology Program in a Multi-Site Manufacturing Environment

-

Part III Manufacturing IT Financials

Part III: Manufacturing IT Financials - Benefits, Costs, and Budgeting

-

Part V: Manufacturing Operations Maturity: Current and

Part V: Manufacturing Operations Maturity: Current and Target State Definitions as Part of a Multi-Site MES Program