AVEVA MES

Manufacturing Execution System

Reject mediocrity and embrace manufacturing excellence with AVEVA MES

Connected shop floor with a 360-degree view of plant KPIs

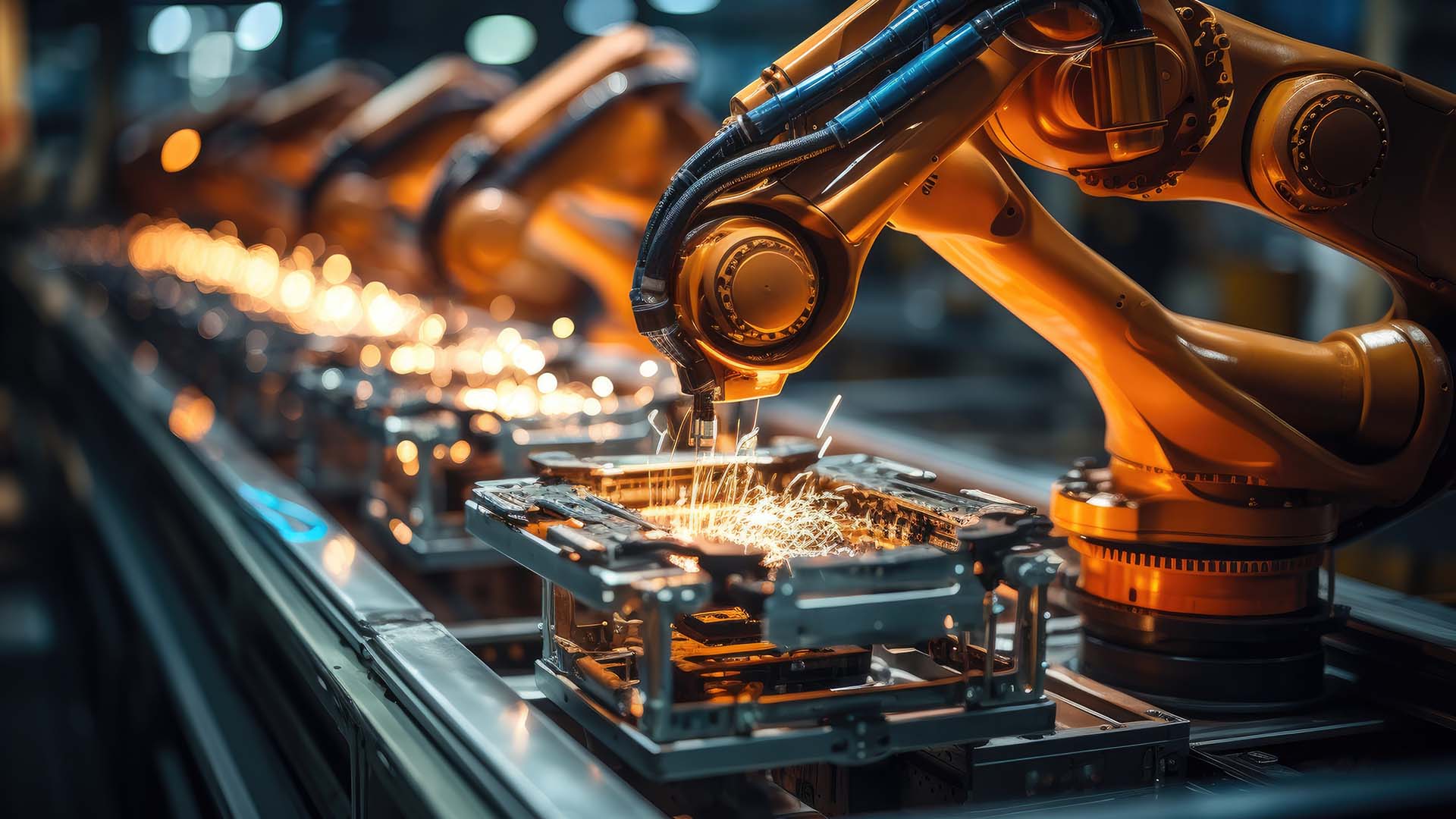

An MES system (Manufacturing Execution System) helps manufacturers optimize production processes by providing real-time data, traceability, and quality management. With real-time reporting, analytics, and full visibility, you can make informed decisions. Beyond lean manufacturing and operational efficiency, AVEVA Manufacturing Execution System (MES) ensures compliance with industry regulations and quality standards.

AVEVA Endorsed System Integrator – how and when?

Thanks to our leadership’s vision and the team’s hard work and determination, we became an AVEVA-endorsed system integrator in 2021.

How did we earn this privilege? Let’s find out.

- Underwent a series of rigorous AVEVA tests

- Impressive expertise in AVEVA and related technologies

- Proven record of project implementations

Key features of AVEVA MES

Do you seek ways to maximize your manufacturing operations’ profitability, quality, and compliance while minimizing costs? The combined might of Roima Intelligence’s manufacturing strategies, along with AVEVA MES’s robust planning and execution tools, will help you achieve the objectives mentioned above.

Multisite manufacturing execution system standardization

AVEVA MES system streamlines multisite manufacturing operations, reducing ownership costs and accelerating smart manufacturing initiatives. It provides a standardized, model-driven approach that allows you to standardize lean practices, operational processes, KPIs, compliance reporting, and supply chain integration across multiple sites. This consistency drives more efficient manufacturing practices and enhances visibility into plant operations, enabling responsive plant and agile supply chain operations.

Model-driven standardization

AVEVA MES system employs model-driven standardization, capturing best practices in templates and libraries. This feature simplifies the rollout and adaptation of standardized practices across multiple sites, ensuring consistency, efficiency, and rapid implementation of manufacturing improvements.

Ready-to-use standard MES models

AVEVA MES system offers ready-to-use standard MES activity and user interface models, significantly reducing the time to value for plant MES solutions and multisite standardization projects. This feature allows for quick implementation, delivering tangible results and improvements faster.

Edge-to-enterprise architecture

AVEVA MES system leverages an edge-to-enterprise architecture, which reduces the cost of standardizing MES across multiple sites. Simultaneously, it unlocks business-wide benefits by providing visibility into plant operations. This visibility translates to a more responsive plant and agile supply chain operations, enhancing overall efficiency and competitiveness.

Production management

Harmonize machine and human efforts to execute work orders and tasks. AVEVA MES ensures that workers adhere to the established workflows in the correct sequence for optimal results.

Workflow management

Thanks to AVEVA MES’s digital capabilities, factory managers can ensure perfect coordination between humans and equipment, resulting in error-free and paperless operations.

Inventory management

Choose the correct materials in proper quantities while obtaining real-time insights into their availability. Even if the materials move to another location, AVEVA MES tracks that.

Quality management

AVEVA MES ensures that your finished goods align with the established quality control and safety standards. Collect machine data and implement corrective measures if necessary.

Data management

Use AVEVA MES’s reporting and analysis tools to gather data from systems, databases, and machines. This data can help managers track the performance of machines, workers, product quality, and other metrics.

AVEVA Manufacturing Execution System datasheet

Datasheet

Discover the full capabilities of AVEVA Manufacturing Execution System. Download the datasheet for detailed information and specifications.

Why choose AVEVA MES?

Roima understands your factory’s requirements and develops innovative strategies to implement AVEVA MES. Over time, your manufacturing unit can experience the following benefits:

Lower costs and higher profitability

Optimized production process, reduced errors, and effective communication between the top and the plant floors reduce costs and increase profits.

Optimized plant performance

With continuous real-time insights into your production cycle, you can make necessary adjustments and improve the production process, increasing revenue and productivity.

Builds formidable brand reputation

Exceed the expectations of stakeholders with improved product quality and increased production output. Eventually, this will build trusted and long-term business partnerships.

Regulatory compliance

Stay informed about the local laws and international regulations related to your industry while ensuring adequate compliance.

Customized configuration and implementation

Roima configures and implements AVEVA MES at your factory while considering your industry, product offerings, and other factors to maximize productivity and profitability.

Insights

Want to know more about AVEVA?

Explore further by scheduling a demo through the form or by reaching out to one of our experts directly. We're here to assist you!

Contact Ulf Johansson

Contact Aki Kössilä

Contact Jan-Erik Mattsson

Contact Hannu Ojasalo