Boost productivity with detailed scheduling

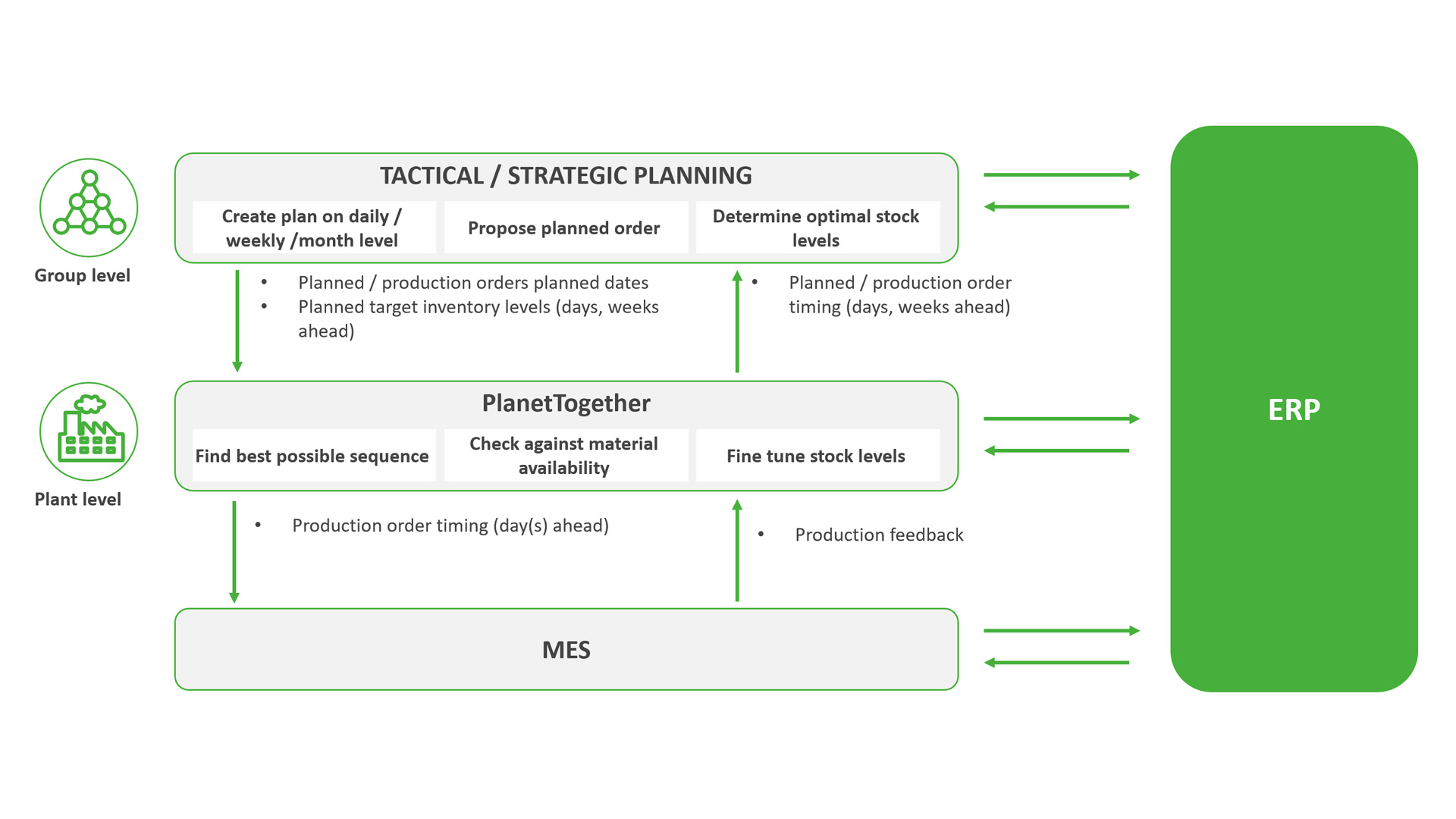

Detailed scheduling connects higher-level planning to the shop floor and operations. It plays a vital role in bringing strategic and tactical plans to action.

However, this task is challenging because dynamic production environments have complex rules for executing strategies on the shop floor. Keeping the plan realistic and executable requires razor-sharp focus and scheduling tools to help planners focus on their duties instead of worrying about updates and other issues.

Roima Intelligence has partnered with the world’s leading advanced planning and scheduling tool, PlanetTogether APS, to help manufacturers increase their productivity. Below, we have outlined some key aspects of considering a scheduling solution.

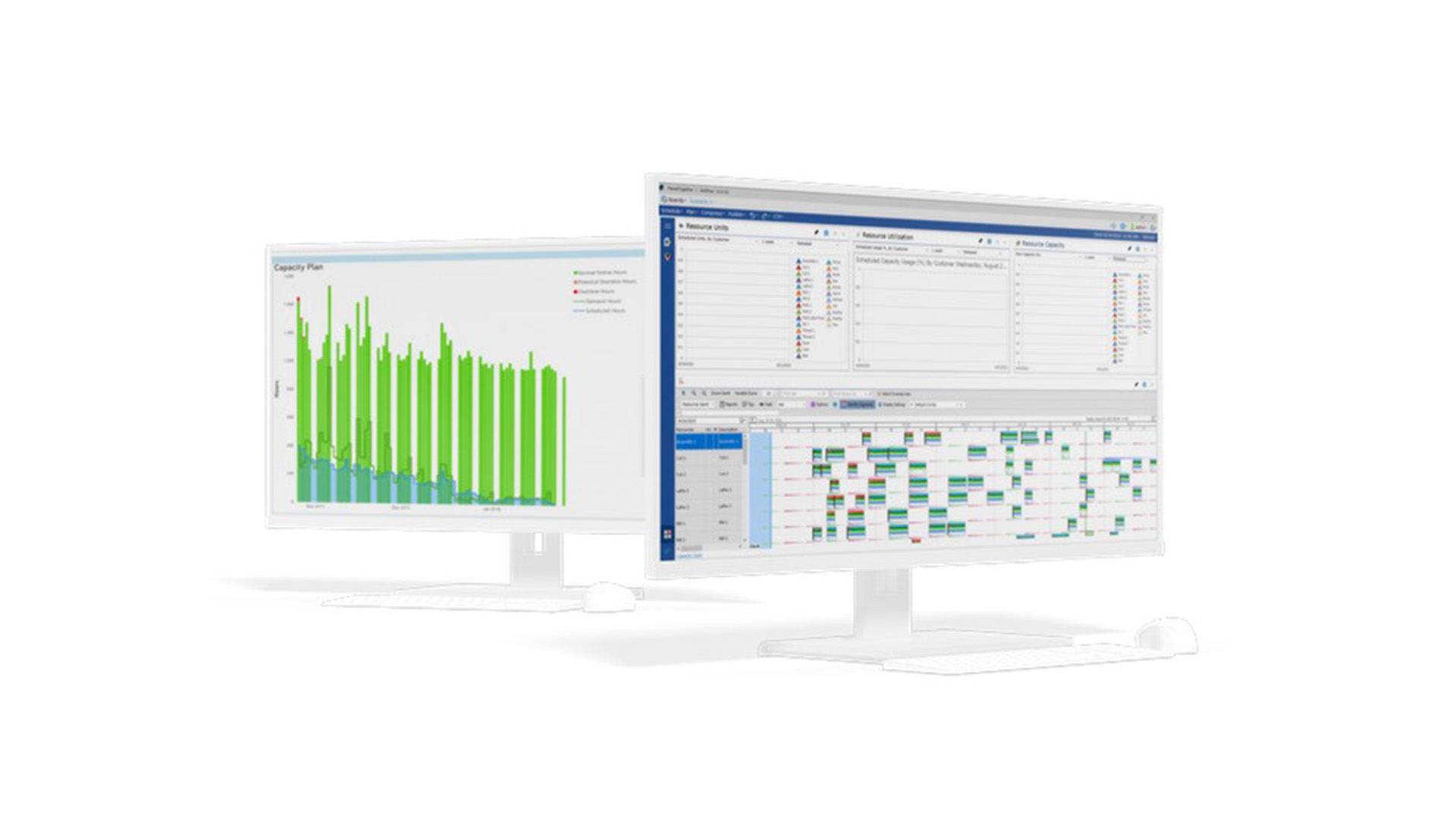

Gantt chart – heart of the scheduling tool

The most crucial aspect of any scheduling tool is the Gantt chart, which shows the operations flow. A flexible view highlighting minute details improves planning efficiency, significantly reducing planners' time looking for specific information in a production schedule. Multiple groups use the Gantt chart. Every group needs access to particular information and a feature to customize views according to their requirements.

A significant chunk of a planner's job is adapting to the situation. He needs a tool that tweaks the plan automatically to align with the defined rules. For example, the subsequent operations will suffer if a player delays a work order operation. Unless the previous operation concludes, new ones cannot begin.

When planners understand that their plan remains feasible after the manual intervention, they can align it with stakeholders' expectations and resolve problems affecting production efficiency.

Stay in total control of your inventory: Plan smart and stay lean

Recent supply chain disruptions have reinforced the importance of material visibility. Scheduling tools must shed light on the consequences of delayed purchase orders. Scheduling tools are a lifesaver for companies because they automatically postpone jobs when materials are unavailable on time.

Moreover, the scheduling tool lists all work orders that suffered delays due to material shortages. Based on the insights, the planner can investigate and identify ways to optimize material purchases and availability.

Similarly, if customers order products late, there is no point in purchasing materials beforehand.

PlanetTogether’s Gannt charts offer a detailed view of inventory levels during the planning horizon. This way, planners can monitor planned inventory levels and create alerts to flag situations where inventory levels rise beyond a certain level.

Optimize the schedule and focus on exceptions

The modern planning approach uses automated logic to create the schedule's first version and identify the pain points later. This approach allows planners to focus on pressing issues instead of performing routine updates. Technology is helpful, but it's unwise to trust it blindly.

Sometimes, the planner’s knowledge and experience play a pivotal role. The so-called tribal knowledge and practical approach to problem-solving is necessary to override the automated logic's decisions. Ultimately, the planner retains complete control of the scheduling process.

When optimizing schedules, planners must adjust to meet customer-specific goals and targets. Understand that every company is unique with different production environments. A perfect production schedule does not exist because priorities can change unexpectedly. Planners must have faith in the schedule optimization process.

An integral aspect of this process is determining priorities in the schedule at any given time. PlanetTogether’s optimization engine rapidly generates schedules according to the current priorities and business requirements using weighted software’s in-built KPIs tools.

Explore options with scenarios

An ideal scheduling tool must have a simulation feature that creates multiple scheduling scenarios without disrupting the present schedule.PlanetTogether APS allows planners to create unlimited “What-If” scenarios to show the impact of prioritizing different, often competing, goals into the schedule.

Creating different scenarios is only half the job. Planners must compare all the scenarios and make well-informed decisions. Comparing and analyzing complex schedules in detail can be challenging and time-consuming. Therefore, using well-defined KPIs facilitates quick comparison and evaluation of these scenarios and helps choose the best schedule.

Labor planning

Companies often want advice on how to include labor in the scheduling process. Employees often face restrictions while performing tasks based on their skills and qualifications. So, employees with specialized skills could be at a major disadvantage. Matching each employee's profile and skills with the scheduling system is not a practical solution.

How do you address such a situation? Pooling employees with specific skills to optimize the scheduling process makes sense. PlanetTogether APS supports planning for skilled labor. Knowing how many employees you need to execute a planned schedule is sometimes enough.

However, in other cases, it would be best to constrain the schedule based on resource availability, especially during schedule optimization. It’s best to model labor usage in detail during schedule optimization to ensure the schedule is realistic and executable.

Planning against forecasts

For some sectors, it is advisable to schedule while adhering to forecasts (wholly or partially). Understand that forecasts must consider uncertainties and last-minute adjustments to ensure agility.

Moreover, it's vital to distinguish between actual and potential orders (flexible orders or orders that may need execution). Knowing the differences will allow you to manage them better. Most importantly, set up forecast netting to remain informed about incoming orders. In this way, you can cut down forecasted orders and eliminate the possibility of duplication.

Integrations

It is not possible to operate a scheduling tool in isolation. Companies must integrate it with MES, high-level supply chain planning, ERP systems, and other systems/software. Ensure that data ownership aligns with business processes during the integration design process, ensuring quick access and modifiability of data in the system.

Roima has extensive experience implementing MES systems, supply planning systems, and other solutions for businesses in diverse industries. Do you use AVEVA MES or have plans to implement it at your company?

The good news is that Roima can provide you with an integrated solution combining PlanetTogether’s APS and AVEVA MES capabilities. This integrated solution can help you overcome production planning and scheduling challenges.

Are you curious to know about this integrated solution? Call Roima to schedule a demo.

-

PlanetTogether

PlanetTogether APS

Additional text for product card: Roima integrates PlanetTogether APS with AVEVA MES, streamlining manufacturing for efficiency. -

Roima Intelligence partners with planettogether to provide

Roima Intelligence partners with PlanetTogether to provide complete MES and APS solutions for manufacturers