Goods receipt

LOGIA WMS feature highlight

Focus on the key elements

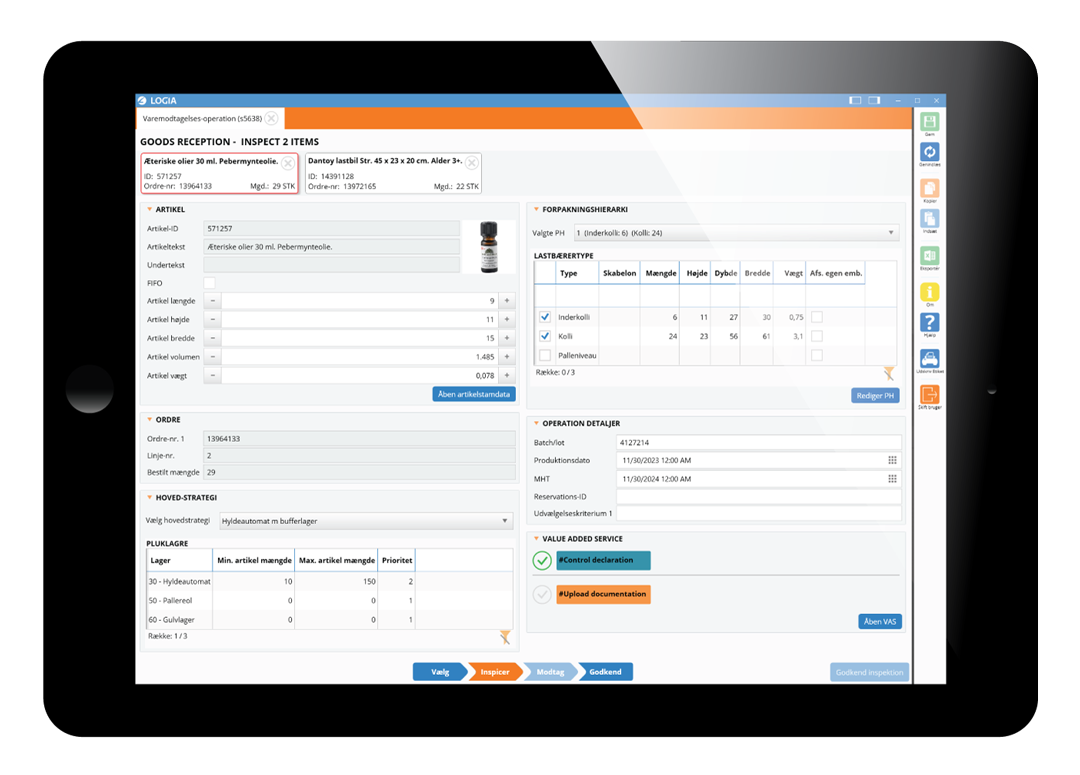

New LOGIA functionality strengthens the goods reception. The initial point of contact for all goods, from suppliers or customer returns, is the reception of goods - a pivotal stage influencing the quality and efficiency of subsequent warehouse processes.

The new LOGIA WMS feature for goods reception is a blend of redesigned old functionality and plenty of new features that enable a thorough and productive goods reception process. It is presented in the LOGIA WMS user interface that operators are accustomed to, offering them a clear overview and concentrated attention on vital aspects of the process.

Complete overview of all product data

Upon receiving goods in the warehouse, the operator scans or inputs the item number/purchase order number, triggering the display of comprehensive order information on the screen. All details about each item are consolidated on a single screen, and missing data are outlined in red frames for easy identification and completion. This encompasses a spectrum of data, ranging from basic master data to master strategy, packaging hierarchy, operational details, and value added services (VAS).

Value added services

Value added services are an integrated part of goods receipt and can be performed in the same handling in LOGIA WMS. This enables simultaneous execution of tasks such as spot checks, quality control, and more. These services ensure that container cleanliness checks, inspections of packaging breakage, and reviews of specific product types are conducted efficiently.

After the operator has examined an item and entered all the necessary data, they will get a detailed overview of the inventory. They can then choose the storage areas where they want to distribute the inventory. LOGIA warehouse management system offers recommendations for optimal storage locations and visually highlights any missing replenishments against registered orders.

Efficient multi-goods reception

The process of receiving pallets with identical goods has been optimized. The operator identifies the first pallet and then continues to add more pallets until the correct quantity is displayed on the screen. This simplified approach reduces repetitive tasks and allows for the handling of goods reception for the same type of item in a single process.

Improvements have been made to the process of receiving mixed pallets. Now, goods can be received simultaneously across multiple lines, which helps to streamline the workflow and improve overall efficiency. Additionally, the optimization has made it faster to receive returned goods. With the help of LOGIA WMS, items can be quickly repositioned to their designated locations, ensuring that returns are processed and shipped out of the warehouse quickly.

The following companies are the first customers to benefit from the new LOGIA goods reception: Besko, ILVA, Arla in Denmark, and Helse Stavanger Hospital in Norway.

Insights

Want to know more about LOGIA WMS?

Explore further by scheduling a demo through the form or by reaching out to one of our experts directly. We're here to assist you!

Contact Karsten Bangshaab

Contact Niels Have

Contact Jesper Højlund