Production Logistics

LOGIA WMS

LOGIA manages the picking and delivery of materials for production

LOGIA WMS manages the picking and delivery of materials for production. Lean principles and electronic Kanban ensure an optimal flow of goods and materials throughout the production process. This means that production capacity can be used to the maximum.

Management of material flows to and throughout production

LOGIA WMS controls picking to production, moving between production cells, and moving to semi-finished or finished goods warehouses. There is successive delivery and collection to and from the production line, so goods do not occupy unnecessary space before and after they are used. This provides optimal flow and punctual and correct stock management.

LOGIA has built-in lean management elements at all levels. All working procedures are supported and organized with a minimum of process stages, and all data is secured and collected in the process. Internal transport is reduced, jobs are carried out appropriately and goods are handled efficiently and flawlessly. The solution is based on scanning or simple registrations.

"Everything is carried out digitally – even our Kanban cards have become electronic, so replenishment happens automatically"

Customer story

- Martin Svenningsen, Supply Chain Manager, Migatronic

Warehouse and production coordination

The warehouse and production employees are online on LOGIA and coordinate the ordering and delivery of goods via the system.

The production operator can see planned production orders on his/her terminal. This generates picking jobs for the warehouse worker, specifying what needs to be picked, when it needs to be delivered, and to which workplace in production. Picking and repositioning of goods are instantly registered in the warehouse management system. This ensures precise inventory management.

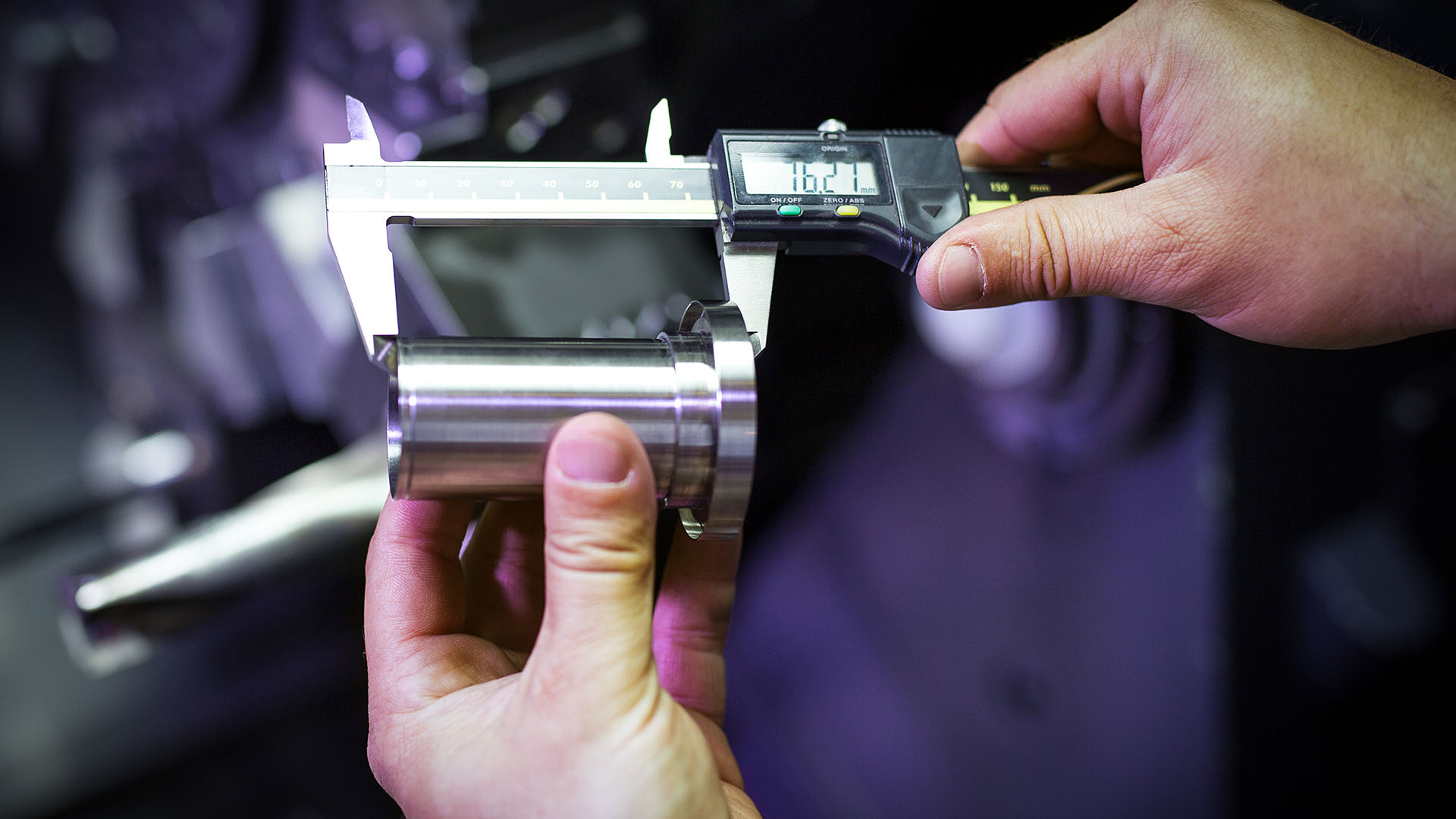

Quality control and traceability

Before, during, and after production, there may be inspections where items need to be checked and values need to be registered.

The values must be registered in the warehouse management system - typically via scanning - before you can move forward in the process.

LOGIA stores the data and it can be used at any time for documentation, traceability, and other purposes.

Insights

Want to know more about LOGIA WMS?

Explore further by scheduling a demo through the form or by reaching out to one of our experts directly. We're here to assist you!

Contact Karsten Bangshaab

Contact Niels Have

Contact Jesper Højlund